PP INK Screen Printing Ink

Ink for Screen Printing on PP Products

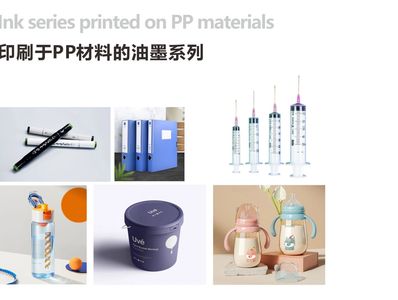

Ink Series for Screen Printing on PP

PP is divided into two categories: rigid and flexible. PP offers excellent physical and chemical resistance, making it suitable for a wide variety of products, including packaging bottles, buckets, crates, baby bottles, pens, folders, syringes, film bags, and hangers. These diverse applications require different ink performance. Our company has developed a series of high-performance inks specifically for printing on PP, including both solvent-based and UV-curable inks, suitable for a wide range of PP products. Different ink types exhibit varying properties, such as gloss, sweat resistance, water resistance, flexibility, and curing properties. Please select carefully.

Excellent Adhesion: PP ink exhibits excellent adhesion to polyolefin materials, ensuring that printed designs or text adhere securely to the surface.

Abrasion and Scratch Resistance: This ink exhibits excellent abrasion and scratch resistance, ensuring that printed products retain their clarity even after extended use.

Chemical Resistance: PP ink exhibits excellent resistance to a variety of chemicals, including alcohol and white spirit, making printed products less susceptible to damage from contact with these substances.

High Gloss and High Hiding Power: The ink exhibits high gloss and hiding power, resulting in vibrant, rich prints.

Environmentally Friendly: Many PP ink products comply with various environmental standards and requirements, such as RoHS and FDA, ensuring environmental friendliness during production and use.

PP ink is widely used for printing on various polypropylene materials, such as stationery folders, cosmetic bottles, medicine bottles, labels, helmets, automotive parts, and electronic accessories. It can also be used for printing on rigid polyolefins such as treated PE bottles, as well as coated metal sheets.

In terms of preparation, the formulation of PP inks can be adjusted to meet specific application requirements and goals. For example, specialized hardeners can be added to improve adhesion and hardness, or different pigments can be used to create different ink colors.

Overall, PP inks have occupied a significant position in the printing industry due to their excellent performance and wide range of applications.

Rainbow Screen Printing Supply Ltd

Add: Room904, Building27, WanKe Square, Daliang, Shunde, FoShan, Guangdong,China.

Tel: +86 757 22606975